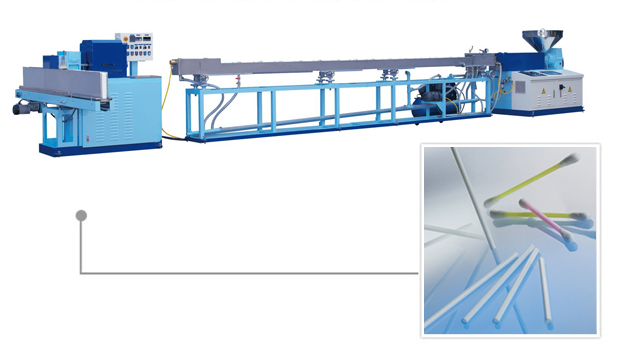

Technical Overview of the JS 284/VCBA Cotton Bud Stick Production System #

The JS 284/VCBA Cotton Bud Stick Making Machine is engineered for efficient and precise manufacturing of cotton bud sticks, utilizing advanced extrusion and automation technologies. Below, you will find a comprehensive breakdown of its features, technical specifications, and operational highlights.

Key Features #

- Material Compatibility: Designed for use with P.P. (Polypropylene) material, supporting a variety of color options.

- Production Capacity: Capable of producing between 2,500 and 3,000 pieces per minute (100 pieces/15g), ensuring high-volume output for industrial needs.

- Precision Manufacturing: Delivers sticks with an outer diameter of 2.5 mm and a length of 72 ± 0.5 mm, maintaining strict tolerances for consistent product quality.

- Extrusion Output: The extruding system supports an output range of 20 to 26 kg/hr, optimizing material usage and throughput.

Technical Specifications #

| Specification | Value |

|---|---|

| Product Outer Diameter | 2.5 mm |

| Product Length | 72 ± 0.5 mm |

| Production Speed | 2,500 - 3,000 pcs/min |

| Extruding Output Range | 20 - 26 kg/hr |

| Screw Diameter | 45 mm |

| Screw L/D Ratio | 25:1 |

| Driving Motor | AC 10 HP + Inverter |

| Thermo-Controllers | 4 sets |

| Vacuum Forming Device | 1 set |

| Vacuum Pump & Motor | 1/2 HP |

| Water Storage Tank | 1 set (6 meters) |

| Take Up Unit | Belt type, 1 set |

| Take Up Motor | AC 2 HP with Inverter, brake clutch |

| Control Panel | 1 set |

| Cutting Wheel | 1 pc with 2 blades |

| Converting Wheel | 1 set |

| Collection Motor | 1/8 HP |

| Collection Box | 3 pcs, stainless steel |

| Machine Dimensions (LxWxH) | 9.5 x 2.55 x 1.5 m |

All specifications and design characteristics are subject to change without prior notice.

System Components #

- Extruder: Features a 45 mm screw diameter with a 25:1 L/D ratio, powered by a 10 HP AC motor and inverter for stable and efficient extrusion.

- Vacuum Water Tank: Includes a vacuum forming device, a 1/2 HP vacuum pump, and a 6-meter water storage tank to ensure optimal cooling and shaping.

- Take Up & Cutting Unit: Utilizes a belt-type take up system, AC 2 HP motor with inverter and brake clutch, and a cutting wheel equipped with two blades for precise stick length.

- Collection System: Stainless steel collection boxes (three in total) and a dedicated 1/8 HP motor facilitate organized and hygienic product handling.

Additional Resources #

For further inquiries or to request detailed information, please visit the Contact Us page.

Related Products:

- PHA/Marine Degradable Straw Making Machine

- PLA/Biodegradable Straw Making Machine

- PP Straw Making Machine

- Straw Bending Machine

- Tetra Pak Straw Packing Machine and Turn Key

- Spoon Straw Making Machine

- Straw Packing Machine/Straw Auto Boxer/Straw Flow Packer/Straw Auto Boxer

- Lollipop Stick Making Machine

- Pen Refill Stick Making Machine

- PP/PET Strapping Band Machine

- PVC Heat Shrinkable Film Making Machine and Turn Key